The following process parameters are relevant for piercing and cutting copper and brass with fiber lasers:

Cut Speed

Back off from the maximum feed rate the process can support by about 10 – 15% to avoid any risk that the cut will extinguish, thereby applying high levels of beam energy to a material in its most reflective state. If in doubt, start at a slower rate than you know the process can support. Allow sufficient dwell time to ensure pierce hole is through before moving the beam to start the cut.

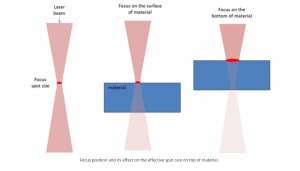

Focus Position

For both piercing and cutting, set the focus position as close to the top surface as the cut quality allows. This minimizes the amount of surface material that interacts with the beam at the beginning of the process, thereby maximizing the power density of the beam, which leads to quicker melting.

Power Setting

Using the maximum peak power available for the piercing and cutting reduces the time in which the material is in its most reflective condition. The chart above can be used as a conservative guide to start the process development.

Cutting Gas

When piercing and cutting copper, using high-pressure oxygen (100-300 psi depending on the thickness) is typically used as the cutting gas to increase the process reliability. When oxygen is used, the formation of copper oxide on the surface reduces the reflectivity. For brass, nitrogen cutting gas works fine.

Post time: Jan-11-2019