When using a fiber laser cutter, cutting speed is an important factor that affect cutting affect. Is the cutting speed of laser cutter the sooner the better? Today RuiJie LASER will tell you.

When the cutting speed is too fast, it will cause the following undesirable results.

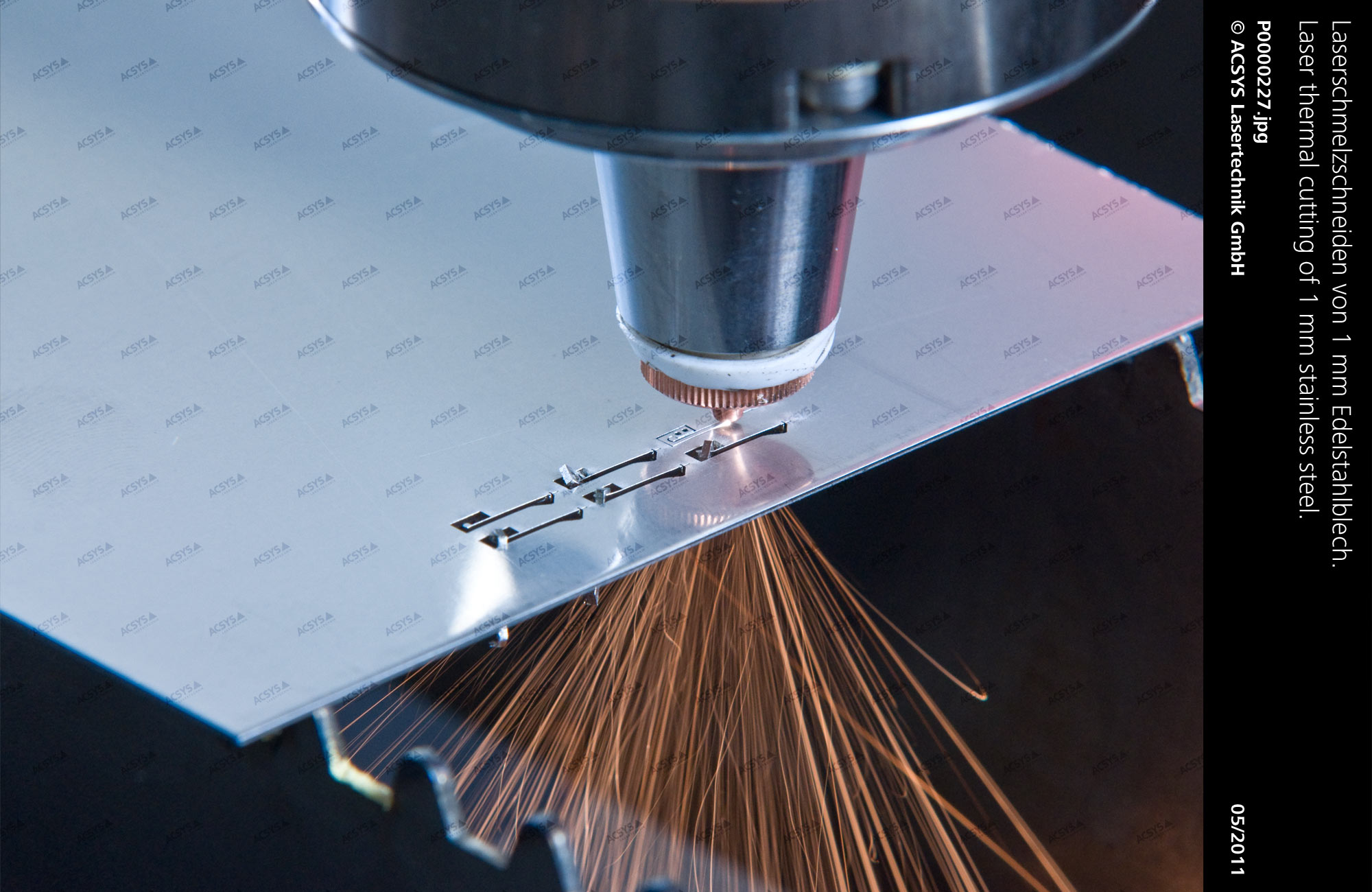

1 Unable to cut, sparks fly.

2 The cutting surface may appear diagonal grain, the lower part produces the melt.

3 The whole section is thicker, but without melt.

On the contrary, when the cutting speed is too slow, it will cause:

1 Over-melting condition, rough cutting surface.

2 Get wider kerf and the kerf dissolves at the sharp angle part completely.

Kevin

—————————————————————

Sales Manager of International Department

WhatsApp/Wechat:0086 15662784401

skype:live: ac88648c94c9f12f

Jinan Ruijie Mechanical Euipment Co.,Ltd

3 Influence cutting efficiency.

Therefore, in order to get a better cutting effect, it is possible to judge whether the feeding speed is suitable by cutting spark.

If the spark diffuses from the top down, the feeding speed is appropriate.

If the spark is tilted backward, it indicates that the feeding speed is too fast.

If the spark is less and not diffuse, condensing together, it indicates that the feeding speed is too slow.

So we can see that too fast and too low speed both affect the machine cutting performance. If you want to learn more knowledges about fiber laser cutting machine, just contact us as soon as possible.

Post time: Jan-22-2019