Why is fiber laser cutting brass and copper so challenging?

1. Their low absorption of infrared laser light makes these metals challenging to cut.

2. Copper and brass (copper-zinc alloy) are good reflectors (and therefore poor absorbers) of the infrared (IR) laser light, especially in their solid state.

3. Pure copper reflects > 95% of near-IR radiation (~ 1 µm wavelength) in its solid state.

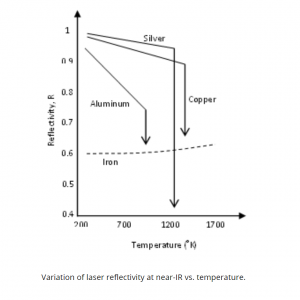

4. The reflectivity of copper and other reflective metals decrease when the metal warms up, and drops sharply once the material melts (e.g. down to <70% for copper in its molten state) as seen in figure below. These metals absorb significantly more laser energy in molten state.

Post time: Jan-11-2019