Since the development of laser technology, laser cutting has always occupied a dominant position in the field of laser processing! Laser cutting is a key strategic industry in my country, and it has been widely used in aviation, aerospace, automobiles, molds, industrial machinery, 3C electronics and other fields. At the same time, higher requirements are put forward for laser cutting technology, and higher power, faster speed, larger format, thicker cutting, brighter cross-section, and straighter have gradually become a development trend in the current market.

With the emergence of high laser powers such as 10KW, 12KW, and 20KW, 10,000-watt laser cutting has also increasingly appeared in the public’s field of vision.

From the point of view of cutting speed, cutting 8mm stainless steel, the speed of 6kW is nearly 400% higher than that of 3kW laser cutting machine. When cutting 20mm thick stainless steel, the speed of 12kW is 114% higher than that of 10kW! It is conceivable that the speed of 40KW will increase by a higher percentage!

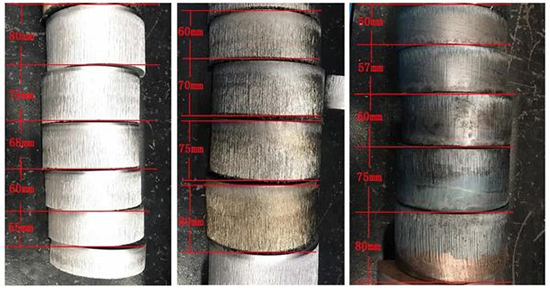

In terms of cutting thickness, the 10,000-watt laser cutting machine has increased the cutting thickness of stainless steel to 80mm.

From the perspective of economic benefits, the price of a 10,000-watt laser cutting machine is less than 40% higher than that of a 6kW machine tool, but the output efficiency per unit time is more than twice that of a 6kW machine, and it saves money. Less manpower! At the same time, the 10,000-watt laser cutting machine can achieve fast bright surface cutting of 18-20mm/s in the cutting application of carbon steel, which is twice the ordinary standard cutting speed.

2. What improvements have been brought about by 10,000-watt laser cutting?

1. Increase the thickness of sheet metal cutting

With the increase of power, the thickness of the cut sheet also increases. The 10,000-watt laser cuts aluminum alloy sheet up to 40mm and stainless steel sheet up to 50mm. With the breakthrough of higher-power 10,000-watt laser technology, the thickness of material cutting will also be further increased. The processing price of thick plates will also be further reduced, which will trigger more laser cutting applications in the field of thick plates, such as shipbuilding, nuclear power, and national defense. As a result, a virtuous circle is formed, and as a result, the application field of laser cutting is further expanded.

2. Improve the efficiency of sheet metal cutting

Higher power also means faster cutting speed and higher efficiency. When cutting stainless steel plates with a thickness of 3-10mm, the cutting speed of a 10kW laser cutting machine is more than twice that of 6kW; at the same time, a 10,000-watt laser cutting machine can reach a speed of 18-20mm/s in the cutting of carbon steel. Bright surface cutting is twice the speed of ordinary standard cutting; it can also cut carbon steel within 12mm with compressed air or nitrogen, and the cutting efficiency is six to seven times the speed of oxygen cutting carbon steel.

Post time: Sep-26-2021