LIEKETSENG LITS'OANELO

- MohlalaRJ-3015A

Melemo ea Metal Fiber Laser Cutting Machine:

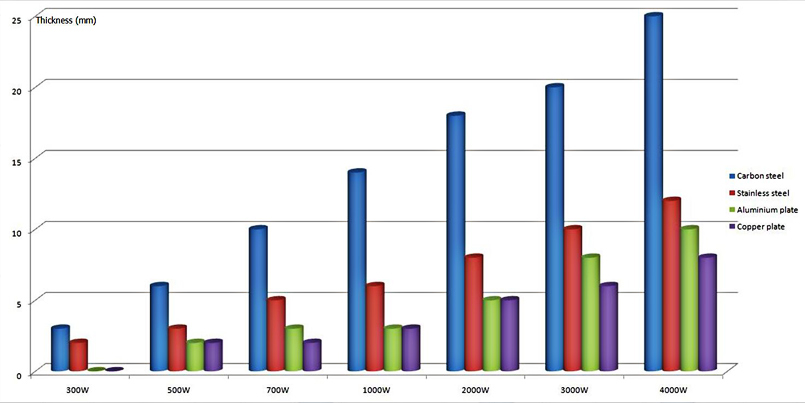

(1) Litšenyehelo tse tlase haholo, hora e 'ngoe le e 'ngoe e ne e sebelisa motlakase oa 0.5W ho 1.5W feela, ho khaola mefuta eohle ea litšepe ka moea;

(2) Li-lasers tsa fiber tsa mantlha tse tsoang kantle, Ts'ebetso e phahameng le e tsitsitseng, nako ea bophelo e feta lihora tse 100,000;

(3) Lebelo le phahameng la ho itšeha le ho sebetsa hantle, lebelo la poleiti ea ho itšeha le ka fihla ho feta limithara tse 10 Tlhokomelo ea mahala ea Laser;

(4) Moeli o boreleli le o motle kapa holimo le ho sotha ho honyenyane;

(5) Enjene ea servo motor le sistimi ea gearing ho netefatsa ho itšeha hantle;

(6) Software e inehetseng e nolofalletsa litšoantšo kapa mongolo ho etsoa kapa ho sebetsoa hang-hang.Ho bonolo ebile ho bonolo ho sebetsa.

| 1.Support AI/PLT/Gerber formats, amohela Mater Cam, Type3 output international standard standard G code.2.Lead-in/out, cutting puseletso, micro-joint, bridging, back back, cutting cutting etc.,3.Ho phunya hangata mekhoa e fumanehang, matla a laser a arohaneng / maqhubu / mofuta oa khase / khatello ea khase / pina ea bophahamo e ka behoa nakong ea ho itšeha le ho phunya, 4.WIFI | |

| Mosebetsi oa Leapfrog:e ntlafatsa haholo ts'ebetso ea ho itšeha. | |

| Photoelectric Edge search :sebaka se potlakileng le ho ntlafatsa ts'ebetso ea ts'ebetso | |

| Taolo ea matla:ho dumella dikgutlo ho pongoa ka ntlha e bohale | |

| Flying cut:haholo-holo bakeng sa letlapa le tšesaane la tšepe, sehiloeng se potlakileng sa mekhoa ea matrix | |

| Ho phunya laser ea Sprint:Sena se thusa ho boloka optics e hloekile le ho ntlafatsa mokhoa oa ho itšeha ka ho sutumelletsa lintho tse vaporised le tse nang le metsi ka ntle ho kerf, haholo-holo bakeng sa tšepe e teteaneng. |

Litokomane tse latelang li fanoe le mochine:

Likopi tsa Bukana ea Tataiso ea Mochini

CE phatlalatso ea tumellano. Delivery Protocol.

Bukana ea software.Mokhanni oa USB bakeng sa bekapo.Ho lemoha hang-hang WIFI le ho netefatsa bothata bo potlakileng.

2THUTO

Ho ipapisitsoe le konteraka, re tsamaisa mochini oa laser ho bareki ba o behang ka polokeho ka nako e behiloeng, 'me re romella moenjiniere ho e kenya sebakeng sa mosebelisi.Tlas'a maemo a mantlha a mochini oa ho kenya, moenjineri o tla phethela mochini oa ho kenya le ho laela nakong ea matsatsi a 1-2 bakeng sa mosebelisi, mme o netefatse hore o makhethe, o hloekile ebile o hlophisehile.Re fana ka koetliso ea tekheniki.Kamora hore ts'ebetso le ts'ebetso li phetheloe, moenjiniere o tla sebeletsa moreki bonyane matsatsi a 5 sebakeng sa bareki kapa fekthering ea barekisi ho fihlela opareitara e khona ho sebelisa mochini.Thupelo ka tsela e latelang:

Litaelo tsa ts'ebetso ea koetliso ea ho bulela le ho tima mochini;

Moelelo oa phanele le liparamente tsa taolo, Letoto la khetho ea litlhophiso tsa koetliso;

Ts'ebetso ea software ea taolo ea koetliso; Tlhokomelo ea mantlha le tlhoekiso ea mochini;

Ho sebetsana le bothata bo tloaelehileng ba hardware; Potso e hlokometsoeng ts'ebetsong;

Ho feta moo, re boetse re fa basebelisi tšehetso ea tekheniki e amanang le lihlahisoa tsa bona tsa tlhahiso.

3 Litšebeletso tsa morao-rao tsa thekiso

Ho fa bareki likarolo tsohle tsa litšebeletso.Re netefatsa:

1. lilemo tse 2 tiisetso ea mochine.

2. Maikutlo nakong ea lihora tse 12 ka tharollo ea bothata bo bong le bo bong.

3. Litšebeletso tsa tlhokomelo ea bophelo ba mochine le hoja tiisetso e fela.

4. Mefuta e mengata ea tšehetso ea hardware le software ka mor'a hore tiiso e fele, thabela ho ntlafatsa mahala.

|

|

Melemo ea Metal Fiber Laser Cutting Machine:

(1) Litšenyehelo tse tlase haholo, hora e 'ngoe le e 'ngoe e ne e sebelisa motlakase oa 0.5W ho 1.5W feela, ho khaola mefuta eohle ea litšepe ka moea;

(2) Li-lasers tsa fiber tsa mantlha tse tsoang kantle, Ts'ebetso e phahameng le e tsitsitseng, nako ea bophelo e feta lihora tse 100,000;

(3) Lebelo le phahameng la ho itšeha le ho sebetsa hantle, lebelo la poleiti ea ho itšeha le ka fihla ho feta limithara tse 10 Tlhokomelo ea mahala ea Laser;

(4) Moeli o boreleli le o motle kapa holimo le ho sotha ho honyenyane;

(5) Enjene ea servo motor le sistimi ea gearing ho netefatsa ho itšeha hantle;

(6) Software e inehetseng e nolofalletsa litšoantšo kapa mongolo ho etsoa kapa ho sebetsoa hang-hang.Ho bonolo ebile ho bonolo ho sebetsa.

| 1.Support AI/PLT/Gerber formats, amohela Mater Cam, Type3 output international standard standard G code.2.Lead-in/out, cutting puseletso, micro-joint, bridging, back back, cutting cutting etc.,3.Ho phunya hangata mekhoa e fumanehang, matla a laser a arohaneng / maqhubu / mofuta oa khase / khatello ea khase / pina ea bophahamo e ka behoa nakong ea ho itšeha le ho phunya, 4.WIFI | |

| Mosebetsi oa Leapfrog:e ntlafatsa haholo ts'ebetso ea ho itšeha. | |

| Photoelectric Edge search :sebaka se potlakileng le ho ntlafatsa ts'ebetso ea ts'ebetso | |

| Taolo ea matla:ho dumella dikgutlo ho pongoa ka ntlha e bohale | |

| Flying cut:haholo-holo bakeng sa letlapa le tšesaane la tšepe, sehiloeng se potlakileng sa mekhoa ea matrix | |

| Ho phunya laser ea Sprint:Sena se thusa ho boloka optics e hloekile le ho ntlafatsa mokhoa oa ho itšeha ka ho sutumelletsa lintho tse vaporised le tse nang le metsi ka ntle ho kerf, haholo-holo bakeng sa tšepe e teteaneng. |

Litokomane tse latelang li fanoe le mochine:

Likopi tsa Bukana ea Tataiso ea Mochini

CE phatlalatso ea tumellano. Delivery Protocol.

Bukana ea software.Mokhanni oa USB bakeng sa bekapo.Ho lemoha hang-hang WIFI le ho netefatsa bothata bo potlakileng.

2THUTO

Ho ipapisitsoe le konteraka, re tsamaisa mochini oa laser ho bareki ba o behang ka polokeho ka nako e behiloeng, 'me re romella moenjiniere ho e kenya sebakeng sa mosebelisi.Tlas'a maemo a mantlha a mochini oa ho kenya, moenjineri o tla phethela mochini oa ho kenya le ho laela nakong ea matsatsi a 1-2 bakeng sa mosebelisi, mme o netefatse hore o makhethe, o hloekile ebile o hlophisehile.Re fana ka koetliso ea tekheniki.Kamora hore ts'ebetso le ts'ebetso li phetheloe, moenjiniere o tla sebeletsa moreki bonyane matsatsi a 5 sebakeng sa bareki kapa fekthering ea barekisi ho fihlela opareitara e khona ho sebelisa mochini.Thupelo ka tsela e latelang:

Litaelo tsa ts'ebetso ea koetliso ea ho bulela le ho tima mochini;

Moelelo oa phanele le liparamente tsa taolo, Letoto la khetho ea litlhophiso tsa koetliso;

Ts'ebetso ea software ea taolo ea koetliso; Tlhokomelo ea mantlha le tlhoekiso ea mochini;

Ho sebetsana le bothata bo tloaelehileng ba hardware; Potso e hlokometsoeng ts'ebetsong;

Ho feta moo, re boetse re fa basebelisi tšehetso ea tekheniki e amanang le lihlahisoa tsa bona tsa tlhahiso.

3 Litšebeletso tsa morao-rao tsa thekiso

Ho fa bareki likarolo tsohle tsa litšebeletso.Re netefatsa:

1. lilemo tse 2 tiisetso ea mochine.

2. Maikutlo nakong ea lihora tse 12 ka tharollo ea bothata bo bong le bo bong.

3. Litšebeletso tsa tlhokomelo ea bophelo ba mochine le hoja tiisetso e fela.

4. Mefuta e mengata ea tšehetso ea hardware le software ka mor'a hore tiiso e fele, thabela ho ntlafatsa mahala.

|

|

SEBELISA MOEKETSI

SEBELISA MOSEBETSI

TS'OA MOKHOA

Re romelle molaetsa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur