TECHNICAL PARAMETERS

- ModelRJ-3015A

Metal Fiber Laser Cutting Machine Advantages:

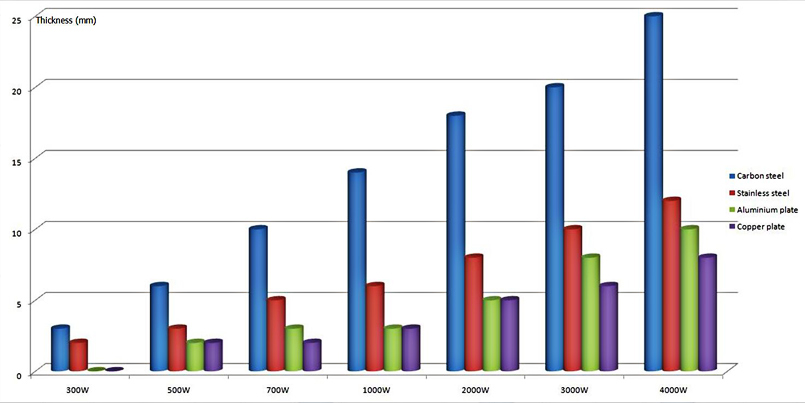

(1) Very low cost, every hour only consumed 0.5W to 1.5W electricity, cutting all kinds of sheet metal by air;

(2) Imported original fiber lasers, High and stable function, lifespan is over 100,000 hours;

(3) Higher cutting speed and efficient, speed of cutting plate can reach over 10 meters Laser free maintenance;

(4) Smooth and fine edge or surface and small distortion;

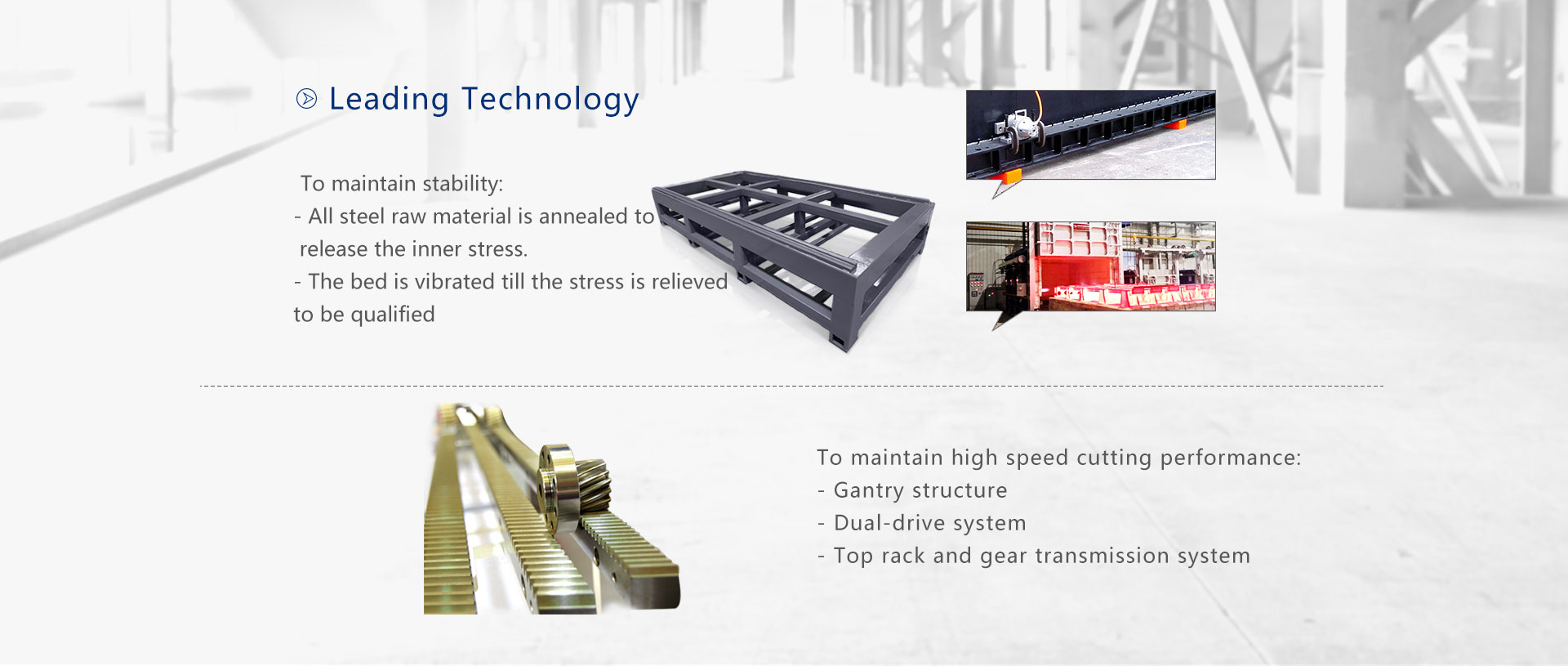

(5) Imported servo motor and gearing system to guarantee precise cutting;

(6) Dedicated software enables graphic or text to instantly designed or processed. Flexible and easy operation.

| 1.Support AI/PLT/Gerber formats, accept Mater Cam, Type3 output international standard G code.2.Lead-in/out, cutting compensation, micro-joint, bridging, back entry, gap cutting etc.,3.Multiple piercing methods available, separated laser power/frequency/ gas type/ gas pressure/ height track can be set during cutting and piercing,4.WIFI remote control panel | |

| Leapfrog function: highly improve the cutting efficiency. | |

| Photoelectric edge search : fast location and improve processing efficiency | |

| Power control: allowing corners to be cut with a sharp angle | |

| Flying cut: especially for thin metal sheet, fast cut of matrix patterns | |

| Sprint laser piercing: This helps to keep the optics clean and improves the cutting process by pushing vaporised and liquified material outthrough the kerf, especially for the thick sheet metal |

The following documentation is supplied with the machine:

Copies of the Machine Instruction Manual

CE conformity declaration. Delivery Protocol.

Software manual. USB driver for backup. WIFI instant detecting and fast problem confirming.

2TRAINING

Based on the contract, we delivery laser machine to customers place safely within the specified time,and send engineer to install at user place. Under the basic conditions of installation machine, engineerwill complete the installation and commissioning machine within 1-2 days for the user, and ensure neat,clean and orderly. We provide technical training. After the installation and commissioning completed,engineer will service buyer operator at least 5 days at buyer place or at seller factory until the operatorcan operate machine. The training as follows:

Training operating instruction of turning on and off machine;

Meaning of panel and control parameters, Training parameter selection range;

Training control software operation ; Basic maintenance and cleaning of the machine;

Dealing with common hardware problem; Noted question in operating ;

In addition to, we also provide users technical support related their producing products.

3After-sale services

To provide customers with all aspects of service. We guarantee:

1. 2 years warranty of machine.

2. Feedback within 12 hours with solutions for every problem.

3. Machine lifetime maintenance services though warranty expires.

4. Wide range of hardware and software support after the warranty expires, enjoy free upgrades.

|

|

Metal Fiber Laser Cutting Machine Advantages:

(1) Very low cost, every hour only consumed 0.5W to 1.5W electricity, cutting all kinds of sheet metal by air;

(2) Imported original fiber lasers, High and stable function, lifespan is over 100,000 hours;

(3) Higher cutting speed and efficient, speed of cutting plate can reach over 10 meters Laser free maintenance;

(4) Smooth and fine edge or surface and small distortion;

(5) Imported servo motor and gearing system to guarantee precise cutting;

(6) Dedicated software enables graphic or text to instantly designed or processed. Flexible and easy operation.

| 1.Support AI/PLT/Gerber formats, accept Mater Cam, Type3 output international standard G code.2.Lead-in/out, cutting compensation, micro-joint, bridging, back entry, gap cutting etc.,3.Multiple piercing methods available, separated laser power/frequency/ gas type/ gas pressure/ height track can be set during cutting and piercing,4.WIFI remote control panel | |

| Leapfrog function: highly improve the cutting efficiency. | |

| Photoelectric edge search : fast location and improve processing efficiency | |

| Power control: allowing corners to be cut with a sharp angle | |

| Flying cut: especially for thin metal sheet, fast cut of matrix patterns | |

| Sprint laser piercing: This helps to keep the optics clean and improves the cutting process by pushing vaporised and liquified material outthrough the kerf, especially for the thick sheet metal |

The following documentation is supplied with the machine:

Copies of the Machine Instruction Manual

CE conformity declaration. Delivery Protocol.

Software manual. USB driver for backup. WIFI instant detecting and fast problem confirming.

2TRAINING

Based on the contract, we delivery laser machine to customers place safely within the specified time,and send engineer to install at user place. Under the basic conditions of installation machine, engineerwill complete the installation and commissioning machine within 1-2 days for the user, and ensure neat,clean and orderly. We provide technical training. After the installation and commissioning completed,engineer will service buyer operator at least 5 days at buyer place or at seller factory until the operatorcan operate machine. The training as follows:

Training operating instruction of turning on and off machine;

Meaning of panel and control parameters, Training parameter selection range;

Training control software operation ; Basic maintenance and cleaning of the machine;

Dealing with common hardware problem; Noted question in operating ;

In addition to, we also provide users technical support related their producing products.

3After-sale services

To provide customers with all aspects of service. We guarantee:

1. 2 years warranty of machine.

2. Feedback within 12 hours with solutions for every problem.

3. Machine lifetime maintenance services though warranty expires.

4. Wide range of hardware and software support after the warranty expires, enjoy free upgrades.

|

|

APPLICATION INDUSTRY

APPLICABLE MATERIAL

CUTTING SAMPLES

Send us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur